Coal based Activated Carbon for Denitrification

Description

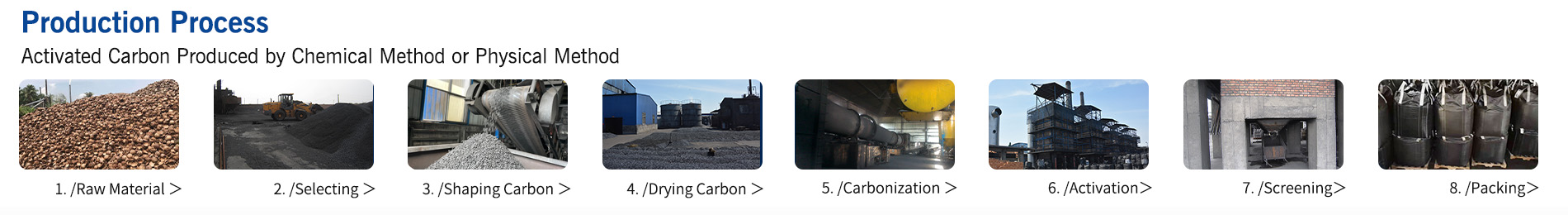

Denitrification activated carbon uses high quality bituminous coal as raw material.It is made through crushing, screening, carbonizing, catalyzing and activation.

It has the advantages of distinctive porous structure, high abrasion and pressure resisting strength and excellent properties of desulfurization and denitrification.

Because of the above properties, coal based activated carbon for denitrification has been widely used in thermal power plants, heating plants and smelteries to eliminate mephitis such as oxides of nitrogen and SO2 from exhaust gas. In addition, it can also be used to resolve acid rain pollution.

Features

- Selected raw materials

- High surface area/Developed pore structure

- Good adsorption capacity for many pollutants

- High hardness and wear resistance

- Low ash content and low density

Items | Test data | Items | Test data |

Iodine Value | 700-1100 mg/g | Packing density | 0.45-0.55 g/cm3 |

Specific surface area | 800-1200 m2/g | Ash | ≤12 % |

Strength | ≥95% | Moisture | ≤5 % |

PH | 8-10 | CTC | 40-70 % |

Remarks: The specification can be customized according to customers’ requirement.

Production & shipment

Henan Shangchen New Material Technology Co., Ltd. has over 30 years history in producing and selling activated carbon.The company can provide specifications and solutions customized services with advanced workshops and equipment.The company will continue to be committed to technological innovation and product quality, and provide customers with better quality activated carbon products and services.