Coal Columnar Activated Carbon

Description

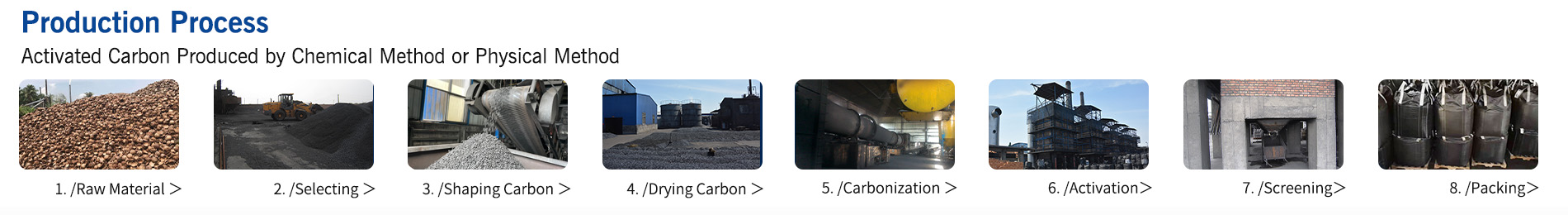

Coal columnar activated carbon uses high quality anthracite or lignite as raw material, and is produced through crushing, mixing, extruding, molding, drying, carbonizing, activating. Coal columnar activated carbon is black cylindrical and has the advantages of logical pore structure, good adsorption capacity, high mechanical strength, easy repeated regeneration, low cost etc.

Product usage:

1.Gas adsorption

2.Organic solvent recovery (benzenes gases toluene, xylol, acetone recovery in acetate fiber industry, CS2 recovery in fibranne producing, etc.)

3.Removing impurity and harmful gas, waste gas recovery.

4.Excessive gasoline recovery of oil refinery, gas station, oil depot.

Features

- Selected raw materials

- High surface area/Developed pore structure

- Good adsorption capacity for many pollutants

- High hardness and wear resistance

- Low ash content and low density

| Items | Test data | Items | Test data |

| Iodine Value | 700-1000 mg/g | Packing density | 0.45-0.55 g/cm3 |

| Specific surface area | 750-1100 m2/g | Ash | ≤12 % |

| Strength | ≥95% | Moisture | ≤5 % |

| PH | 8-11 | CTC | 40-70 % |

Remarks: The specification can be customized according to customers’ requirement.

Production & shipment

Henan Shangchen New Material Technology Co., Ltd. has over 30 years history in producing and selling activated carbon.The company can provide specifications and solutions customized services with advanced workshops and equipment.The company will continue to be committed to technological innovation and product quality, and provide customers with better quality activated carbon products and services.